Air quality monitoring is an increasingly important part of managing construction site safety. With growing awareness of how dust, emissions, and airborne pollutants affect health, it’s vital for job sites to actively track environmental conditions.

Whether a project involves excavation, demolition, or the use of diesel-powered equipment, the potential to release harmful particles into both indoor air and outdoor air is substantial.

Construction sites are a major source of air pollution, contributing to local emissions of particulate matter, volatile organic compounds (VOCs), carbon monoxide, and nitrogen oxides. These pollutants affect not only workers on-site but also surrounding communities and the broader environment.

Continuous air quality monitoring is essential to protect workers, comply with OSHA and EPA standards, and reduce the industry’s impact on climate change and its contribution to greenhouse gases.

Why Construction Sites Need Air Quality Monitoring

The need to monitor air quality on construction sites stems from both health and legal responsibilities. Construction activities that disturb soil and use heavy machinery can generate high concentrations of airborne hazards like dust, VOCs, asbestos, and ozone.

Combustion processes from generators and other equipment release nitrogen dioxide, sulfur dioxide, and carbon monoxide, all of which can lead to respiratory problems and other harmful effects.

Workers often operate close to these key pollutants, sometimes in enclosed or semi-enclosed areas where indoor air quality becomes a concern. The temperature, humidity, and site location can all influence how pollutants behave. For example, still air in a narrow trench may trap gases, increasing exposure risks.

Beyond health, air monitoring helps ensure compliance with federal and state regulations. Agencies like the EPA require that contractors assess, measure, and document pollutant levels, especially when working near schools, residential zones, or environmentally sensitive areas. Failure to do so may lead to fines, project delays, or reputational damage.

Common Airborne Hazards on Job Sites

Construction work regularly disturbs materials and generates pollution that contaminates both ambient air and indoor air quality. These airborne hazards include:

- Particulate matter (PM2.5 and PM10): Fine and coarse dust particles from cutting, grinding, and demolition work. These can penetrate deep into the lungs and cause lasting health damage.

- Carbon monoxide (CO): A poisonous gas emitted from fuel-burning equipment and transportation vehicles. In enclosed spaces, CO buildup can be fatal.

- Volatile organic compounds (VOCs): Emitted from paints, adhesives, sealants, and fuel, VOCs contribute to smog and can cause both short-term irritation and long-term adverse effects.

- Nitrogen oxides (NOx): Including nitric oxide and nitrogen dioxide, these pollutants are formed during combustion and play a role in ozone formation.

- Sulfur dioxide (SO2): Released from diesel machinery and power generation equipment, it can aggravate asthma and other respiratory conditions.

- Asbestos fibers: Disturbed during demolition, especially in older buildings, and known to cause cancer.

- Other gases and mold spores: Released during excavation and in damp conditions, they can lead to respiratory irritation.

Construction can also produce liquid particles and hydrocarbons that reduce air quality and harm worker health.

Worker Safety and Health Risks

Exposure to construction-related air pollution has both immediate and long-term health effects. In the short term, poor air quality can cause respiratory irritation, dizziness, nausea, and fatigue. Over time, repeated exposure to air pollutants like PM2.5, CO, and NOx can lead to chronic lung disease, cardiovascular problems, and even neurological issues.

These health risks are often worsened by a lack of visible symptoms, making it difficult for workers to know when they are in danger. Many gases are odorless and colorless. Without real-time monitoring, there is no way to accurately determine whether the air is safe to breathe.

Studies and research continue to highlight construction workers as one of the occupational groups most at risk for pollution-related illness. A proactive approach to air quality monitoring is therefore critical not only for health but also for workforce retention and productivity.

Construction Air Quality Regulations and Compliance

Construction firms must adhere to strict air quality standards set by both federal and state authorities. The Environmental Protection Agency (EPA) sets air quality standards for outdoor air, particularly around particulate matter, ozone, and nitrogen dioxide.

Meanwhile, OSHA regulates indoor and workplace exposure to carbon monoxide, asbestos, and other harmful substances.

Depending on the site type, firms may need to maintain monitoring records, perform risk assessments, and implement pollution reduction strategies. Special rules often apply when working near schools, hospitals, or areas with known radon presence or elevated present-day pollution risks.

Failure to act on violations can result in fines, halted work, or even loss of contract. Compliance requires the use of accurate, calibrated monitoring systems, documentation of pollutant levels, and regular evaluation of on-site activities that could affect air quality.

Monitoring Tools and Technologies Used in Construction

Today’s construction sites benefit from a range of monitoring technologies that can help manage both indoor air quality and ambient air pollution. These tools include:

- Portable sensors: Lightweight devices used to detect CO, ozone, dust, and VOCs in real time.

- Fixed air quality monitors: Stationed at key locations on the site to continuously measure background levels of pollutants.

- Wearable devices: Used by workers in high-risk zones to monitor personal exposure to key pollutants.

- Dust monitoring stations: Provide detailed reports on airborne particulates, often linked to software dashboards for on-site alerts.

Most of these tools rely on accurate calibration and regular maintenance to deliver dependable data. Integrating these systems with project management workflows ensures a more proactive and responsive safety strategy. Air quality monitoring networks can be built using these systems to track site conditions and evaluate performance over time.

The Role of Weather APIs in Monitoring and Forecasting

Environmental conditions such as wind speed, humidity, temperature, and precipitation can influence the concentration and movement of pollutants. A sudden change in weather can stir up dust, shift emissions downwind, or worsen smog on hot, stagnant days.

This is where weather APIs come into play. By incorporating forecast data, site managers can anticipate climate-related air quality shifts and modify operations accordingly. For example, high winds may delay excavation, or high ozone forecast levels could postpone painting with VOC-heavy materials.

Using Visual Crossing’s Weather API gives construction teams access to hyperlocal, hourly weather and pollution data, improving their ability to plan around environmental risks and maintain performance while minimizing exposure.

How to Respond to Poor Air Quality Events

When a site experiences poor air quality, managers should be ready with a response plan. Helpful options include:

- Adjusting work schedules to cooler hours when ozone levels are lower

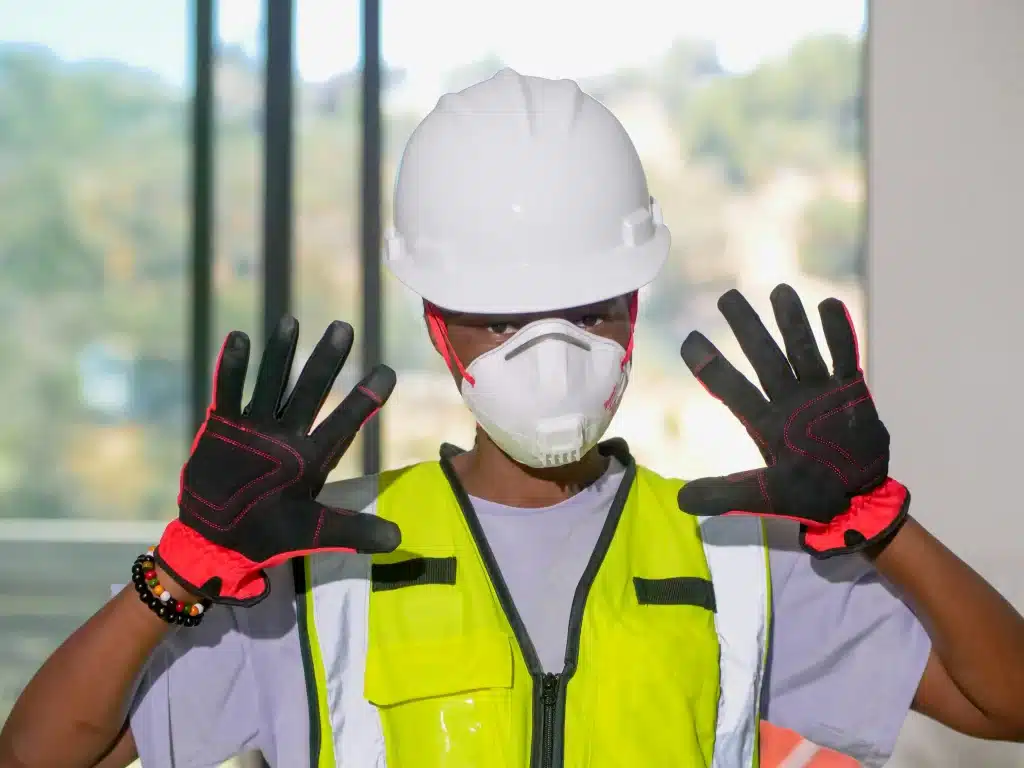

- Requiring PPE such as respirators or N95 masks

- Enhancing air conditioning and filtration in indoor workspaces

- Relocating workers away from high-exposure zones

- Pausing non-essential activities during extreme pollution events

Quick, informed action is key. Monitoring networks should be set up to detect threats, alert supervisors, and ensure corrective action is taken to reduce risk and restore safe working conditions. Methods for intervention should be documented and refined over time.

Building a Safer, More Compliant Job Site

Monitoring air quality is a key component of responsible construction management. A robust strategy protects not only workers but also nearby communities and the broader environment. It helps firms meet regulatory obligations, avoid penalties, and demonstrate a commitment to health, safety, and sustainability.

As construction practices evolve to address both productivity and environmental impact, incorporating air quality data into daily site management becomes more valuable. It improves the operation of equipment, reduces downtime, and supports long-term planning in the face of climate change.

By proactively tracking emissions, reducing noise and airborne hazards, and responding to risks in real time, construction leaders can build safer sites today and a healthier future for everyone. Responsible practices benefit both individual projects and the broader construction industry.